Feeding method: magnetic suction/adsorption/blowing (optional)

1. Supports deep holes, inclined holes, curved surfaces, surfaces of different heights, stainless steel screws, and meson screws;

2. Intelligent detection of missing locks, floating locks, sliding teeth, floating height, and automatic recording of floating height coordinates;

3. Equipped with independently developed motion control card, foolproof programming, touch screen displaying torque and locking efficiency;

4. Equipped with a Weilun Tong human-machine interface touch screen, the lock status is dynamically displayed, and the electric batch speed and torque can be monitored in real time;

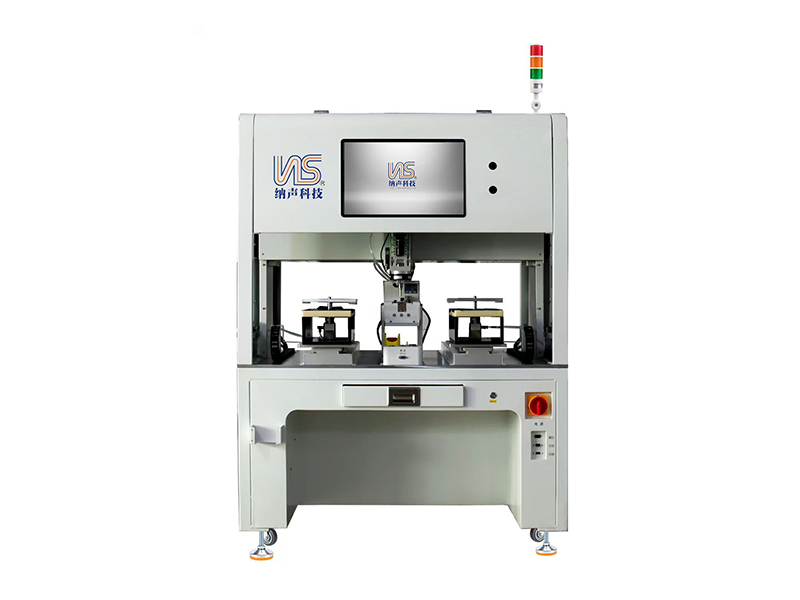

·Feeder

·Servo electric batch

·CCD visual positioning

·Information scanning

·Intelligent electric batch

·Safety cover

·Safety grating

| Product model | NS.SF.7771-2TLS-E | NS.SF.7771H-2TLS-E |

| Equipment itinerary | 700 * 650 * 100mm (single-sided X * Y * Z) | |

| Locking range | 250 * 150 * 100mm (single-sided X * Y * Z) | |

| Transmission mode | Stepper motor+belt+synchronous wheel | Servo screw |

| Positioning accuracy | ±0.02mm | |

| Control system | Multi axis motion control card+touch screen+coordinate editing handle | |

| Feeding method | Vacuum suction/magnetic suction/blowing type | |

| Quantity of feeders | 1 group/2 groups | |

| Locking efficiency | 1.5S-2.1S/PCS | |

| Program capacity | 100 groups | |

| Input power supply | AC220V 50HZ | |

| Power | AC220V /800W | |

| Input air pressure | 0.4-0.6MPa | |

| External dimensions | L1000mm*w1100mm*H1350mm(长*宽*高) | |

| Body weight | 180KG | |