Hello! Welcome to the website of Dongguan City Acoustic Electronic Equipment Technology Co., Ltd.!

+86-400-822-9298

1. Automatically and quickly capture Mark positioning, search and recognize product contours, automatically correct and compensate to ensure precise laser welding position

2. "Surface heat release", fast heating speed, and small impact of solder joints on surrounding heat

3. Suitable for complex surfaces, polygons can also be welded

4. After the laser is transmitted and focused through the laser fiber, it is irradiated onto the surface of the workpiece and the tin wire for constant temperature melting of tin, forming a stable and reliable soldering effect

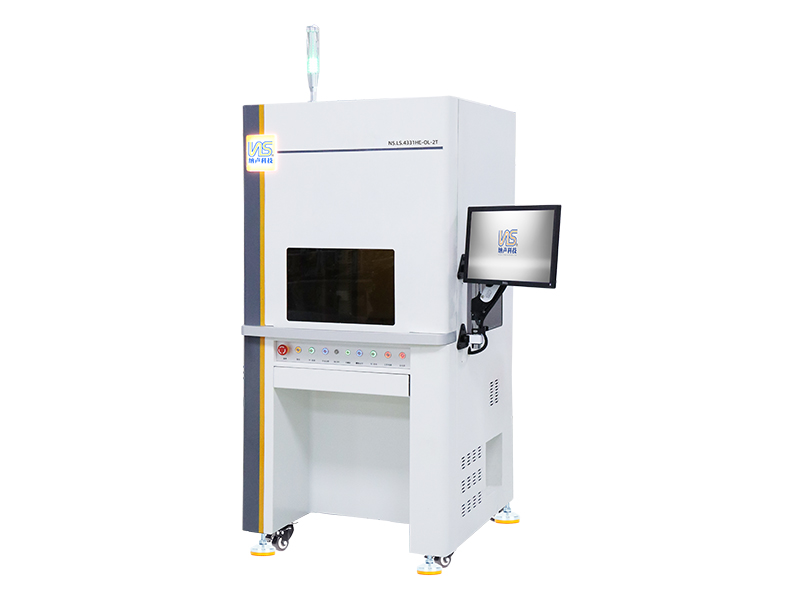

| Product Name | Offline six axis back-to-back servo vision glue dispensing robot |

| Motion Range | NS.SP.4331HE-OL-2T |

| Locking Range | (X1/X2/Y1/Y2/Z1/Z2/) 400/400/300/300/100/100mm |

| Maximum load | (Y/Z) 10KG/5kG |

| Moving speed | (X/Y) 0.1-800mm/S (Z) 0.1-300mm/s |

| Repetitive precision | ± 0.04mm (X/Y); ± 0.02mm (Z) |

| Storage memory | 64G/120G |

| Welding efficiency | High precision AC servo system (up to 24 bit encoder) |

| Laser Type (optional) | Fiber/semiconductor laser |

| Laser power (optional) | 150/300W (fiber), 200W (semiconductor) |

| Visual positioning system | Standard 1.32 million pixel industrial camera (Pixel options: 3M or 5M) |

| Control mode | Based on MC professional controller |

| Programming mode | Keyboard and mouse+display |

| Visual resolution | 0.01 * 0.01mm/Pixel |

| Light source | LED ring, coaxial light source, automatic adjustment |

| Recognition range | 14 * 14mm |

| Input power | AC110V/220V/50-60V HZ 1.4kW |

| Working environment temperature and humidity | 5-40 ℃/20-90% |

| Dimensions | W * L * H: 810 * 960 * 1700mm |

| Body weight | 150Kg |