Hello! Welcome to the website of Dongguan City Acoustic Electronic Equipment Technology Co., Ltd.!

+86-400-822-9298

1. Adopting servo motors and grinding screw modules to ensure high-precision, high-speed, high-efficiency, and high consistency operation of the system, the platform's repeated positioning accuracy can reach 0.01mm

2. Equipped with an independent core pneumatic controller or injection valve, it achieves high-precision stable discharge and precise trajectory control of fluids. In a non-contact manner, it can achieve a stable glue line width or glue point diameter of 0.25mm

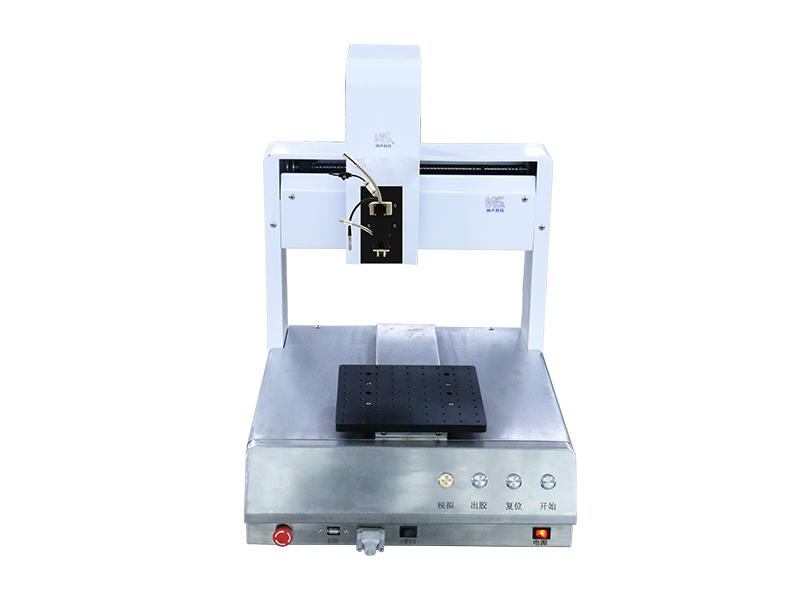

| Product Name | Three Axis Servo Vision Adhesive Robot | ||

| Product Model | NS.SP.920H | NS.SP.930H | |

| Range of motion | 200 * 200 * 100mm | 300 * 300 * 100 | 400 * 400 * 100mm |

| Maximum load | 8kg/4kg | ||

| Moving speed | (XY) 0.1-500/(Z) 300mm/s | ||

| Decomposition ability | 0.01mm | ||

| Repetition accuracy | ± 0.02mm | ||

| Drive mode | Precision servo stepper motor | ||

| Operating mode | PTP& amp; amp; CP | ||

| Transmission mode | Precision screw | ||

| Motion interpolation power | Any route in 3D three-dimensional space | ||

| Programming mode | Teaching Box/PC | ||

| I/0 Signal | 4Inputs/40Outputs/12Inputs/Outputs/ | ||

| Teaching Box Control | RS232 | ||

| Input power | AC 110V/220V/50-60HZ | ||

| Power | 500W | ||

| Working environment temperature | 5-40 ℃/20-90 ℃ | ||

| Dimensions | L554 * W525 * H650mm | L654 * W625 * H | L754 * W725 * H700mm |

| Body weight | 35kg | 45kg | 55kg |

| Function configuration | 1. Adjustment frame assembly; 2. Pneumatic injection valve; 3. Piezoelectric injection valve; 4. Screw valve; 5. Needle type | ||