Hello! Welcome to the website of Dongguan City Acoustic Electronic Equipment Technology Co., Ltd.!

+86-400-822-9298

1. Automatically and quickly capture Mark positioning, search and recognize product contours, automatically correct and compensate to ensure accurate dispensing position

2. Non contact spray valve, achieving smaller dispensing diameter and wider applicability

3. High price ratio under high-performance conditions

4. The stroke, motion speed, and acceleration of each axis are customized according to the requirements

5. MES, rubber valve, needle sensor Ethernet、 The barcode scanner can be upgraded

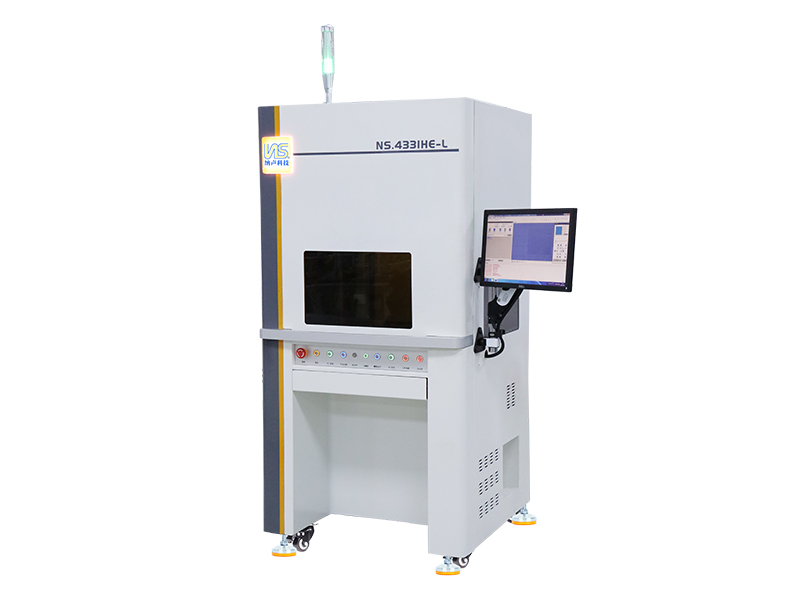

| Product Name | Offline Servo Vision Adhesive Robot |

| Product Model | NS.SP.4331HE-OL |

| Motion Range | (X/Y1/Y2/Z-axis) 400/300/100/100mm |

| Maximum load | (Y/Z-axis) 10KG/5KG |

| Moving speed | (X/Y-axis) 0.1-800mm/s Z-axis 0.1-300mm/s |

| Repetition accuracy | XYZ:+/-0.01mm |

| Storage memory | 64G ultra large capacity high-speed fixed disk file storage (customizable 120G) |

| Drive mode | High precision AC servo system (highest configuration) 24 bit encoder) |

| Operating mode | Industrial control computer |

| Transmission mode | Silent screw precision module (grinding stage) |

| Visual positioning system | Standard 1.32 million pixel industrial camera (optional 3M or 5M) |

| Control mode | Based on MC professional controller |

| Programming mode | Keyboard and mouse+display |

| Visual resolution< | 0.01 * 0.01mm/Pixel (adjustable) |

| Light source | LED ring, coaxial light source (communication protocol automatic dimming) |

| Recognition range | 14 * 14mm |

| Input power | AC 110V/220V( Internal switching) 50-60HZ 1.4kW |

| Working environment temperature and humidity | 5-40 ℃/20-90% non condensing |

| External dimensions | W * L * H: 810 * 1700mm |

| Body weight | Approximately 100kg |

| Function configuration | Standard features: 1. Four axis dual motion platform 2. Four axis visual recognition dispensing system 3. Cleaning glue Calibration module 4. Needle cylinder valve |

| Optional functions: 1. Laser altimeter 2. Automatic weighing balance 3. Glue liquid Position detection 4. Spray glue valve, precision screw valve |