Model: NS.CL100ZD.5NB

Product Overview:

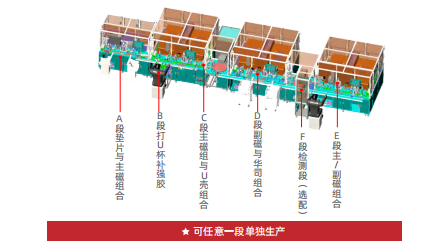

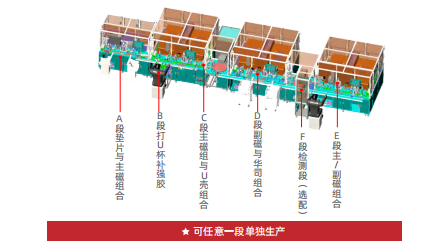

1. Realize fully automatic feeding of auxiliary magnets, Huasi, main magnets, gaskets, and U-shaped vibrating disks, and assemble and bond them automatically through fixtures;

2. The whole machine is equipped with automatic loading and unloading, dispensing, pressure holding, drying, and auxiliary material receiving functions

Product functions:

Realize fully automatic feeding of Huasi, magnets, and push plate machines, with Huasi, magnets, and U-cup centering function Huasi is divided into positive and negative aspects The pusher has no noise (Reduce the noise impact of the vibrating disc).

The pressure holding module ensures that all products are individually pressurized with a pressure holding head to ensure even compression and even distribution of adhesive.

The equipment comes with a shortage detection function, which detects whether the components are missing by detecting the height of the product components at the assembly station.

.

In high-end configuration, it can be equipped with adhesive and magnetic gap AOI detection function (optional), and the spray valve non-contact dispensing (optional) can effectively improve the bonding yield of the finished product, and realize the main and auxiliary magnetic vibration magnetization and assembly bonding

Product Capacity:

UPH: 1200 PCS/H (depending on the customer's product process)