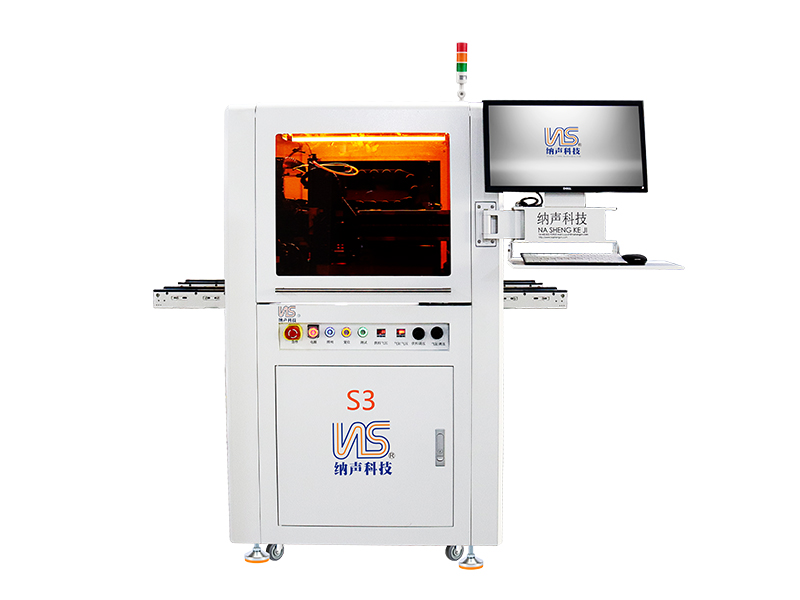

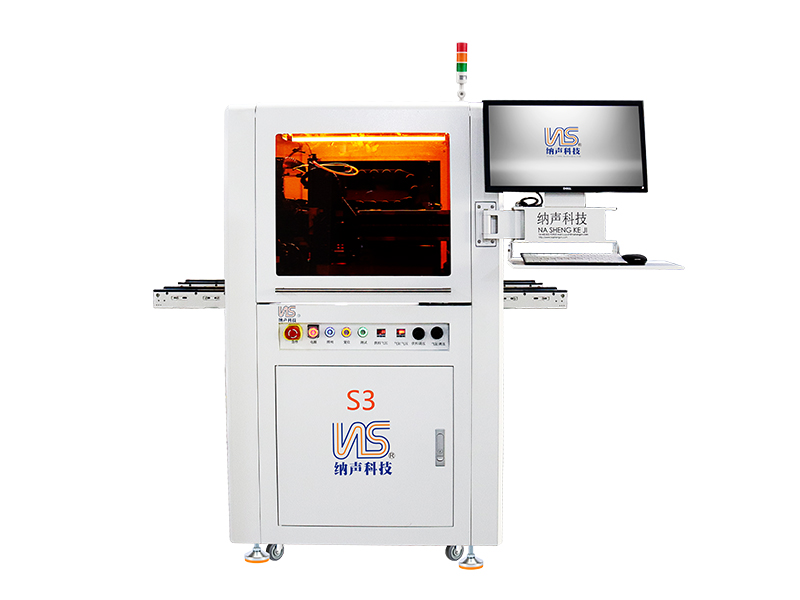

| S3 series S3 series |

|

|

| Product model | NS. SP.461HE-PL | NS. SP.4661HE-PL |

| Range of motion | (X/Y/Z)400/600/50mm | |

| Maximum load | (Z-axis) 5KG (optional brake module can reach 7KG) | |

| Moving speed | (X/Y axis) 0.1-800mm/s (Z axis) 0.1-400mm/s | |

| Repetitive accuracy | ±0.01mm | |

| Track widening range | Monorail: 60-470mm, maximum dispensing length: 475mm | Dual track: 60-200mm, maximum dispensing length: 475mm |

| Docking height | Ground to track belt height: 900mm (± 30mm adjustable) | |

| Drive mode | Servo motor+screw module | |

| Transmission mode | Stepper motor+channel | |

| Operation mode | Visual guidance | |

| Programming mode | Keyboard and mouse+monitor | |

| Visual positioning system | Standard high pixel industrial camera | |

| Identification scope | 30mm*30mm | |

| Power | 2000W | |

| Input power supply | AC 110V/220V (internal switching) 50-60HZ | |

| Working environment temperature and humidity | 5-40 ℃/20-90% non condensing | |

| External dimensions | L840*W1140*H1500mm | |

| Body weight | About 650kg | About 800kg |

| Product Features |

1. Equipped with a heavy system to achieve closed-loop glue volume 2. Professional high-speed dispensing system, with all common dispensing command processes such as highly controllable points, straight lines, polylines, arc lines, circles, rectangular circles, filling three-dimensional spatial trajectories, etc 3. Configurable scanning system, integrated management of the entire production line 4. Automatically and quickly capture Mark positioning, search and recognize product contours, automatically correct and compensate, and accurately dispense glue positions |

1. Dual track design for higher efficiency 2. Professional high-speed dispensing system, with all common dispensing command processes such as highly controllable points, straight lines, polylines, arc lines, circles, rectangular circles, filling three-dimensional spatial trajectories, etc 3. Configurable scanning system, integrated management of the entire production line 4. Automatically and quickly capture Mark positioning, search and recognize product contours, automatically correct and compensate, and accurately dispense glue positions |