|

Brand |

ACOUSTIC |

Name |

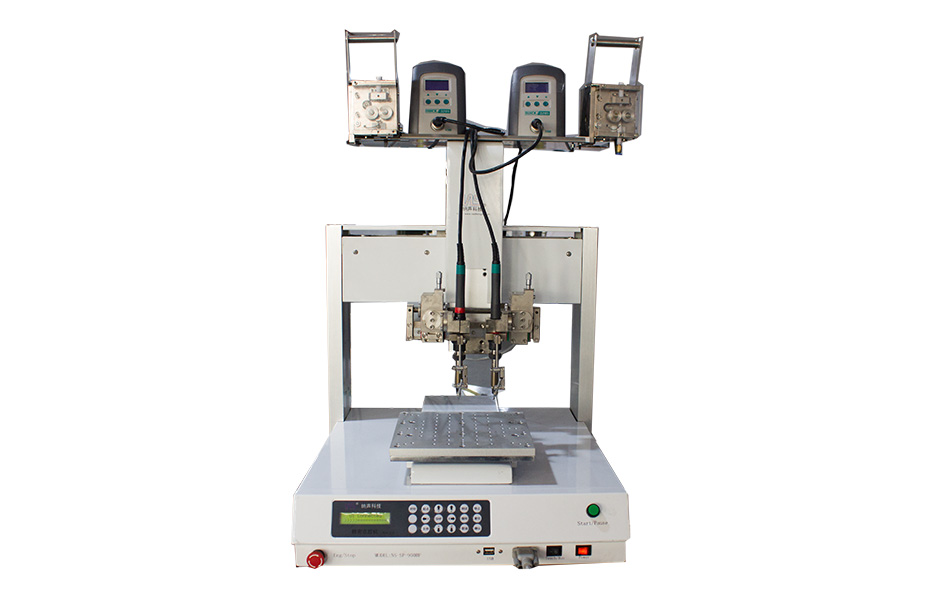

Triaxial soldering robot |

|

Model |

NS-SP-930/940/950B |

Dimensions |

380*410*500mm |

|

Product number |

NS-SP-940/950/960BF-Y |

||

|

product name |

Three-axis dispensing robot |

||

|

Range of motion |

225/200/80mm |

300/300/100mm |

400/400/100mm |

|

Maximum load |

5kg/2.5kg |

||

|

Moving speed |

0.1-500mm/s |

||

|

Decomposition ability |

0.01mm |

||

|

Repeatability |

±0.02mm |

||

|

Program storage quantity |

Large capacity high-speed file storage, can store 999 files. Each 56000 points (supports U disk copy) |

||

|

Display method |

TeachPendantLCD |

||

|

Motor system |

Japanese micro stepping precision motor |

||

|

Operating mode |

PTP&PC |

||

|

transfer method |

Timing belt |

||

|

heating method |

High frequency eddy current heating |

||

|

Temperature range (°C) |

200-480 |

||

|

Applicable tin wire diameter (not broken tin) (mm) |

0.3-0.6 |

||

|

Applicable tin wire diameter (broken tin) (mm) |

0.6-1.5 |

||

|

Input power |

AC 110V/220V (internal switching) 50-60HZ |

||

|

heating power |

90/150W |

||

|

Working environment temperature and humidity |

5-40 ° C / 20-90% no condensation |

||

|

Dimensions |

380*410*500mm |

||

|

Body weight |

35kg |

||

|

Common application range |

Electroacoustic, inductive and other components |

||

|

product features |

1. Independent temperature control system, closed loop control and automatic compensation, welding temperature is more accurate |

||