|

Brand |

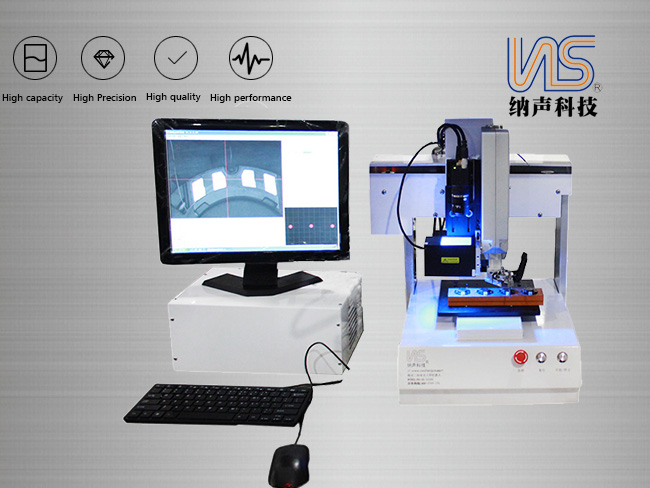

ACOUSTIC |

Name |

Three-axis automatic point vision welding robot |

|

Model |

NS-DH-925BE |

Dimensions |

380*410*500mm |

|

Product number |

NS-DH-925BE |

|

product name |

Three-axis automatic point vision welding robot |

|

Range of motion |

225/200/100mm |

|

Maximum load |

5kg/2.5kg |

|

Moving speed |

0.1-500mm/s |

|

Decomposition ability |

0.01mm |

|

Repeatability |

±0.02mm |

|

Program storage quantity |

Large capacity high-speed file storage, can store 999 files. Each 56000 points (supports U disk copy) |

|

Display method |

TeachPendantLCD |

|

Motor system |

Japanese micro stepping precision motor |

|

Operating mode |

PTP&PC |

|

transfer method |

Timing belt |

|

Visual positioning system |

Industrial CCD |

|

Programming mode |

PC |

|

Resolution |

0.011*0.011mm/Pixel |

|

Light source |

LED light source |

|

Working environment temperature and humidity |

5-40 ° C / 20-90 ° C no condensation |

|

Power |

350W |

|

Input power |

AC 110V/220V (internal switching) 50-60HZ |

|

Working environment temperature and humidity |

5-40 ° C / 20-90% no condensation |

|

Dimensions |

380*410*500mm |

|

Body weight |

35kg (without host) |

|

product features |

Details are as follows |

product features

1. Intelligent visual recognition, automatically record several spot welding positions according to the setting area, and process several products at a time.

2, simple and convenient programming, can directly input the coordinates of the solder joints, realize online / offline programming, can teach the reproduction of the coordinates of the solder joints

3. It is suitable for welding metal wire or enameled wire with 0.02-0.3mm wire diameter. It adopts advanced pressure sensor and electronic control system to accurately control output voltage, time and welding pressure.

4. Using the built-in current sensor to monitor the quality of each solder joint, it has stable output and precise regulation of welding energy; small solder joint, good conductivity, reduced signal attenuation, accurate positioning of the welding head and long service life.

5, intelligent periodic spot welding head milling, remove oxide layer, reduce downtime. Real-time feedback on stress.