|

Brand |

ACOUSTIC |

Name |

Wireless charging coil winding machine |

|

Model |

NS-LE-240F |

Dimensions |

1000*800*1700mm |

|

Product number |

NS-LE-240F |

|

product name |

Wireless charging coil winding machine |

|

using electric |

AC220V |

|

Use air source |

0.4Mpa-0.7Mpa |

|

Winding bonding mode |

Hot melt or alcohol soluble |

|

Spindle speed |

Max 3000rpm |

|

AC servo motor |

Double spindle 750W cable shaft 400W mold axis 200W, left and right axis 200W. Upper and lower shaft 400W |

|

Shaft angle |

360 degrees 1 circle Set the unit 0.1 degree |

|

Axis stop accuracy |

Positive and negative 0.1 degrees |

|

Applicable wire diameter |

0.02mm-1.5mm |

|

Lead position |

Arbitrarily set |

|

Lead length |

50-120mm |

|

Maximum outer diameter |

100mm |

|

Maximum |

20mm |

|

Cable accuracy |

0.005mm |

|

Number of stations |

4 |

|

Extrusion function |

Have |

|

Wire breaking mechanism |

Pneumatic scissors |

|

Programming input method |

NC program |

|

Working environment temperature and humidity |

5-40 ° C / 20-90% no condensation |

|

Total power |

5500W |

|

Total Weight |

300kg |

|

Production capacity |

3200pcs-4000pcs/h (take 10 rounds of alcohol line as an example) |

|

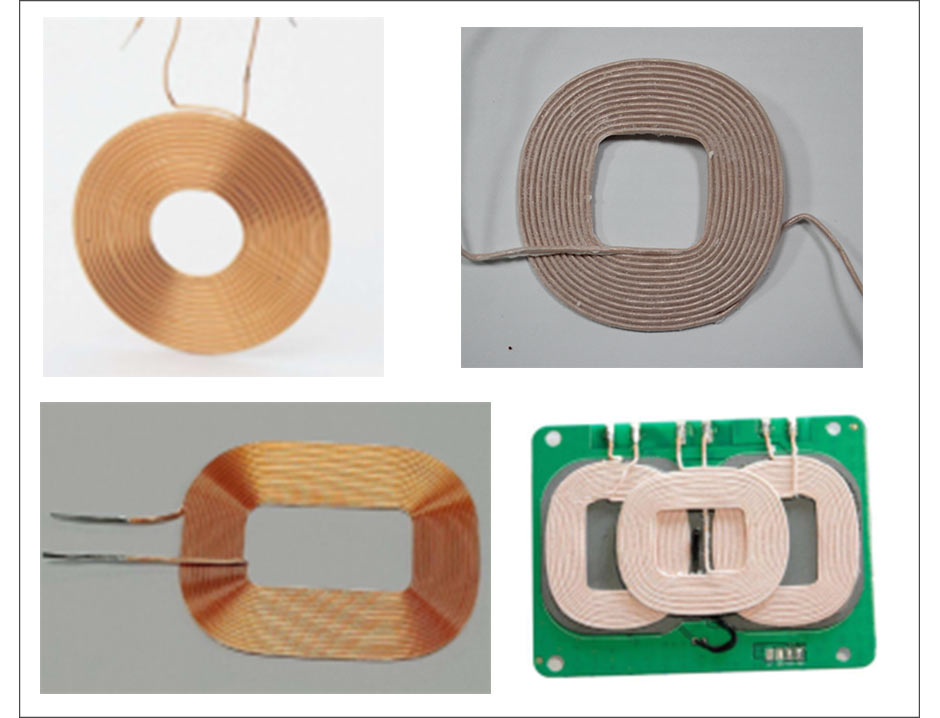

Suitable product |

Alpha winding, single layer wireless charging coil, multi-layer wireless charging coil |

product features:

1. The left and right axis coaxiality is ±0.01mm, and the straightness is ±0.005mm;

2. Servo motor is provided by Delta

3. Solenoid valve, the cylinder is provided by Yadeke and Japan CKD;

4. The winding axis and the cable axis are positioned accurately. Configuration: TBI grinding screw, HIWIN rail, MITSUBOSHI timing belt;

5. Design electrical wiring for electromagnetic compatibility (EMC), wiring is neat and clear, clear;

6. The hot air gun airflow is precisely adjusted by the flowmeter, and the value is visually visible;

7. The cylinder action exhaust is drained to the outside of the chassis and discharged through the muffler;

8. It can be used to bypass the hot air line and the acetone line at the same time. The acetone addition method is to adjust the quantity quantitative injection. Compared with the drop acetone method, the control quantity is accurate, the quantity is small, the acetone does not splash everywhere, and the appearance of the product is not acetone. Acetone line, round, 10 circles, 3200-4000/hour